Here’s a common modern headache: a small business in Ohio needs 50 custom hoodies for a local tournament in three weeks. The old playbook? Email a factory overseas, hope the samples are right, wire a deposit, wait for a slow boat from across the Pacific, pray nothing goes wrong, and pay a small fortune in express shipping if they’re late. It was a slow, risky, and rigid dance.

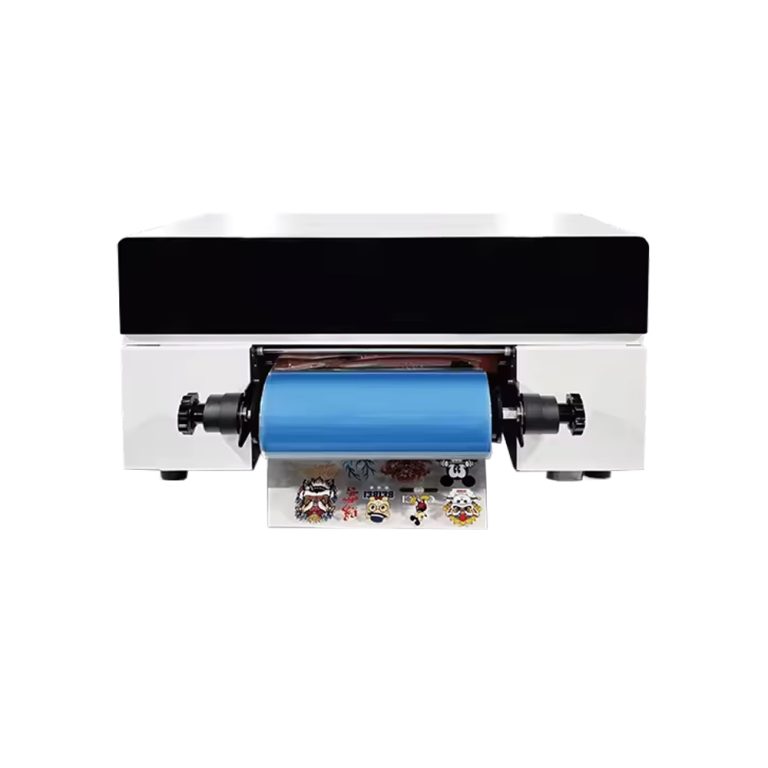

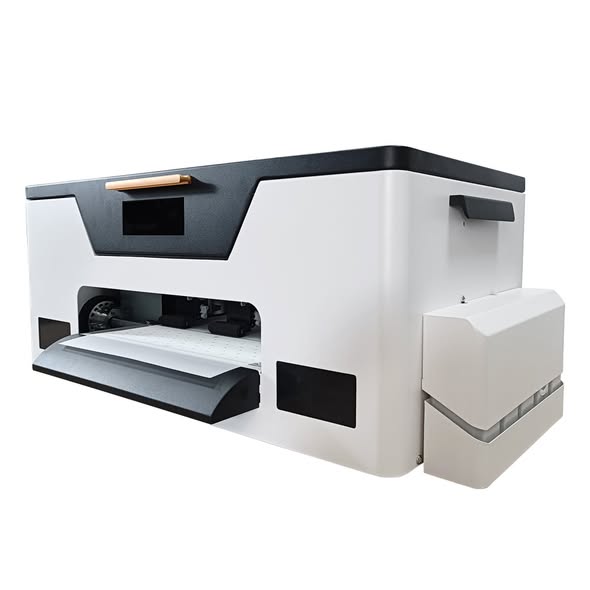

But today, that order is increasingly handled by a machine not much bigger than a microwave sitting in a garage in Ohio. That machine is a UV DTF printer, and it’s quietly flipping the script on how custom products are made and sourced worldwide. It’s turning global procurement from a months-long logistical odyssey into a local, afternoon project.

What UV DTF Actually Does

First, let’s demystify the tech. DTF stands for “Direct-to-Film.” Instead of printing directly onto a t-shirt (like DTG) or burning screens (like traditional screen printing), a UV DTF printer does something brilliantly simple:

It prints your full-color design, with a white base layer, onto a clear, sticky plastic film.

A built-in UV light instantly cures (dries and hardens) the ink.

You end up with a flexible, durable, sticker-like transfer.

The magic happens next. With a standard heat press, you can then place that transfer onto not just a cotton t-shirt, but virtually anything: polyester, nylon, canvas bags, hats, ceramic mugs, phone cases, even wood or metal. It’s wildly versatile, requires minimal skill to start, and produces professional results.

Why This Clicks with Today’s Global Procurement Nightmares

For years, the rule was “consolidate and offshore” to cut costs. But recent global shocks have exposed the fragility of long, complex supply chains. The new procurement buzzwords are resilience, agility, and near-shoring. This is exactly where a desktop UV DTF printer becomes a strategic tool.

From 60 Days to 60 Minutes: It collapses the timeline from concept to product. An idea can be a physical item ready to sell or ship the same day. This kills the need for massive overseas inventory orders and the risk of being stuck with unsold stock.

The Death of the “Minimum Order Quantity” (MOQ): Factories abroad have high MOQs to make the economics work. For a small business or startup, ordering 500 pieces was a huge risk. With UV DTF, the MOQ is one. You can profitably make a single, unique item. This enables true on-demand production.

Unshackled Creativity & Hyper-Localization: You’re no longer limited to a factory’s catalog. A local brewery can print limited-edition merch for a single event. A school can print team jerseys with each player’s name without a two-month lead time. The design freedom is total.

The Bigger Picture: Micro-Factories and the New Economics

This isn’t just about a cool printer. It’s about the rise of the distributed micro-factory. Instead of one massive plant serving a continent, you have hundreds of small nodes—print shops, entrepreneurs, even existing retailers—who can now act as local production hubs.

The global procurement trend is no longer just about finding the cheapest supplier. It’s about building a responsive, low-risk network. Smart businesses are now doing a mix: they might still source blank garments in bulk from overseas for cost (a simple, stable supply chain), but they insource the high-value, customized printing locally using technology like UV DTF. This blends global scale with local speed.

A Tool for a New Era

The UV DTF printer is more than a piece of hardware; it’s an enabler of a new supply chain philosophy. It directly addresses the demand for faster turnaround, smaller batches, and reduced risk that defines modern commerce.

For procurement managers, it’s a tool for building resilience. For entrepreneurs, it’s a ticket to the market without a giant warehouse. For consumers, it means more unique, locally relevant products, faster.

The next time you see a vibrant, custom product at a local market or a small online store, there’s a good chance its journey didn’t start in a distant port. It was likely dreamed up, printed, and finished down the street—powered by a small machine that’s proving that in today’s world, often the most efficient supply chain is the shortest one.