Let’s be honest, shopping for a printer can feel like decoding alphabet soup: DTG, DTF, UV… It’s confusing. If you’re looking at the booming world of custom apparel, you’ve probably zeroed in on DTF (Direct-to-Film) as a great option. But now there’s this new kid on the block: UV DTF. Is it just a fancy version of the same thing? Not quite. For a buyer, the difference isn’t just a technical spec—it changes your daily workflow, your costs, and what kind of business you can run.

Let’s break it down in plain English, using a simple example.

Meet Jenny. She starts a small custom print shop from her garage. She gets orders for colorful t-shirts, hats, and tote bags from local schools and small businesses. She needs a printer that’s versatile, relatively easy to use, and can handle low to medium volumes. She’s looking at both a standard DTF setup and a UV DTF printer.

The Core Difference: Powder vs. Light

This is the big one. It’s like the difference between baking cookies and using a food dehydrator. Both make a snack, but the process is totally different.

Standard DTF Printer: Think of this as the “powder and bake” method.

It prints your design with water-based ink onto a special PET film.

The wet ink must then be sprinkled with a fine, hot-melt adhesive powder. This is a crucial, sometimes messy, step.The powdered film goes into a curing oven or dryer. The heat melts the powder, encapsulating the ink and turning it into a flexible, glue-backed transfer.

You then use a heat press to apply that transfer to a shirt.

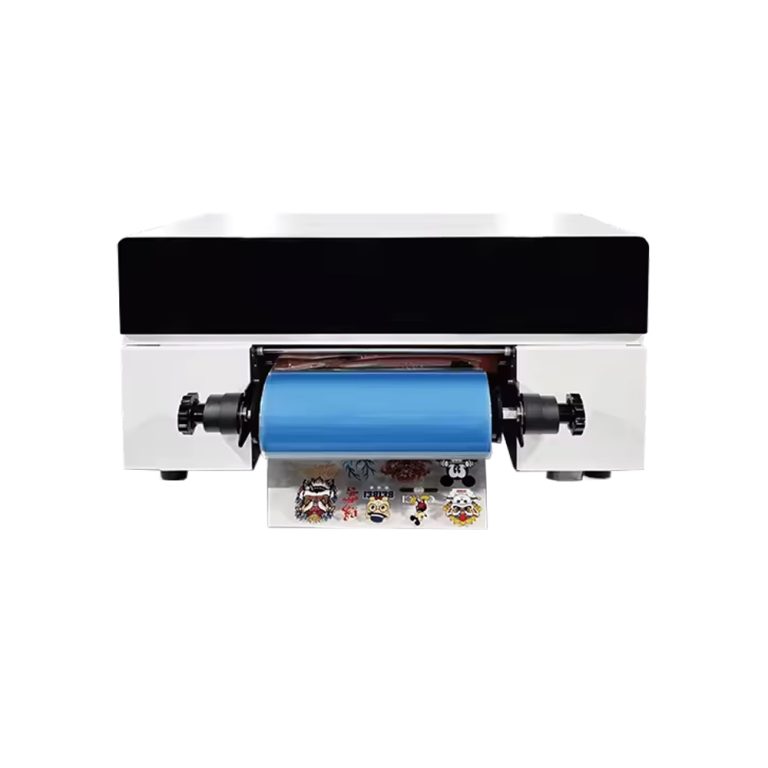

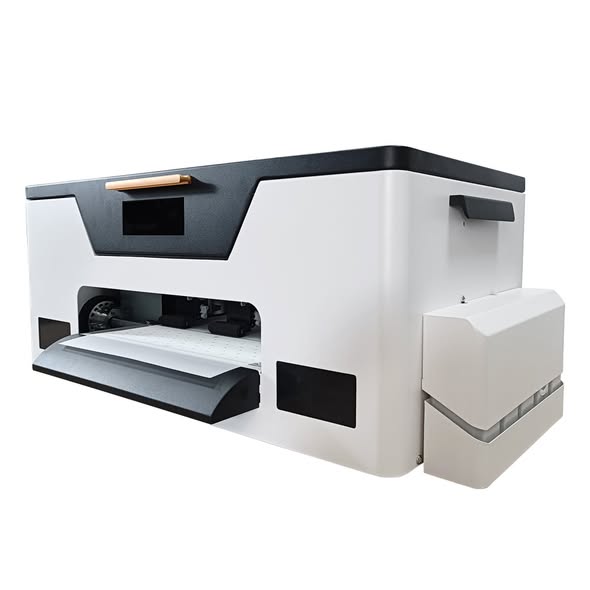

UV DTF Printer: This is the “instant cure” method.

It prints your design with a special UV-curable ink onto a clear, pre-adhesived PET film. Notice: No powder.

A small UV LED light follows the print head, instantly curing (hardening) the ink the moment it hits the film. It’s dry to the touch immediately.

You now have a finished transfer. You weed it (peel off the excess film) and heat-press it onto a garment.

For Jenny, this means: With standard DTF, she has to manage the powder station—keeping it even, cleaning up static-cling powder, and running the curing oven. With UV DTF, the process is cleaner and has fewer steps right off the printer.

So, Which One Should You Choose?

Back to Jenny.

If Jenny’s business is mostly bulk orders (50+ shirts of the same design), the per-print cost of standard DTF might be lower, and the softer hand-feel is a plus. The slower workflow is less of an issue for large batches.

If Jenny’s business is heavy on quick, one-off jobs, mixed products (mugs and shirts), and she values a clean, fast operation, then the UV DTF printer is likely worth the higher initial investment. The speed and versatility let her fulfill orders the same day.

Don’t get hung up on which technology is “better.” It’s about which is better for your specific business. If you’re patient, cost-sensitive, and focus on fabric, standard DTF is a proven workhorse. If you value speed, cleanliness, and want to offer a wider range of products with a simpler process, UV DTF is the modern tool for the job.

Your best move? Find a supplier that can send you sample transfers made on both types of equipment. Stick them on a black shirt, feel them, wash them, and see which result you prefer for the products you want to sell. Your customers—and your workflow—will thank you.